|

Rated voltage |

AC 230V |

|

Rated current |

3.3A |

|

Frequency |

50/60Hz |

|

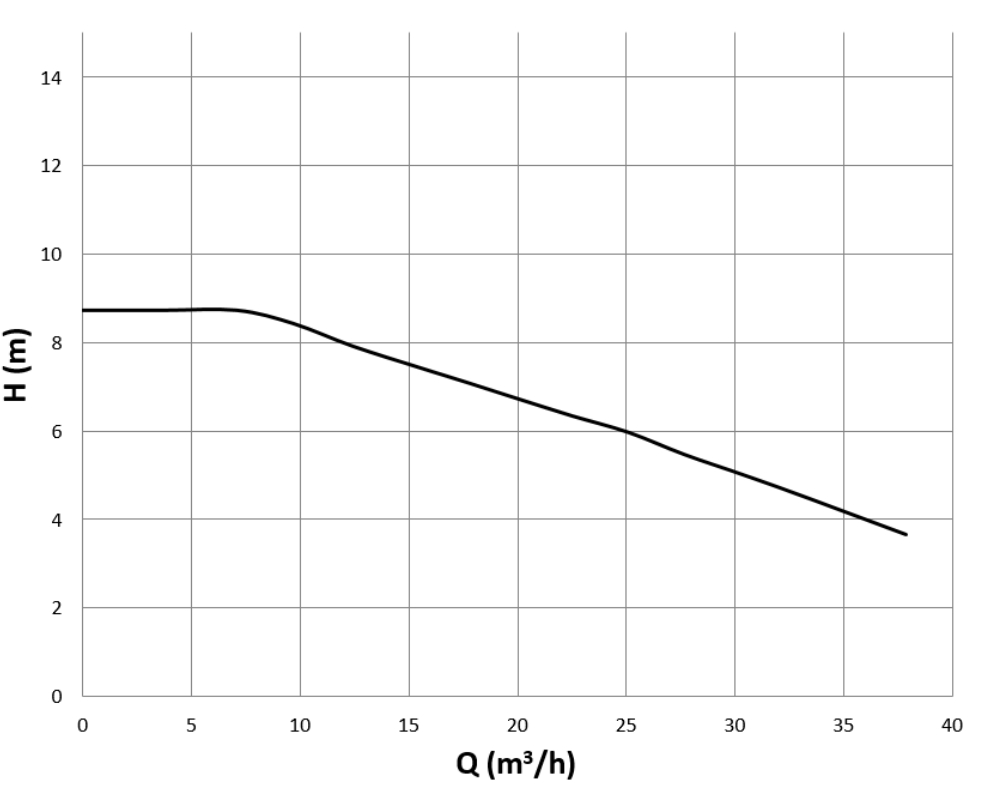

Maximum flow |

37 m³/h |

|

Maximum head |

8 m |

|

Maximum power |

750 W |

|

Rated flow |

28 m³/h |

|

Rated head |

5 m |

|

System pressure |

1.0MPa |

|

Insulation class |

H |

|

Temperature grade |

TF110 |

Item NO.:

Mega S 80-8F

1. Product application scope

Mega S 80-8F Proseries circulating pump is mainly used for the water circulation in homeheatingand

domestic hot water system.

2. Product Certification

Plan to obtain evidence:GS、CE、EMC、RoHS、REACH、EEI≤0.23-Part2

Note: RoHS and REACH are third-party testing reports.

1、AUTO mode control

When the electric pump is in AUTO mode, the electric pump will automatically make necessary adjustments according to the actual system characteristics.

2、Constant speed mode

When the electric pump is in the constant speed operation mode, the electric pump runs at a constant speed.

3、Proportional mode

When the pump is in the proportional operation mode, the head increases linearly with the change of flow rate.

4、Constant pressure mode

When the pump is in constant pressure mode, the head keeps a constant value as the flow rate changes.

5、Temperature control mode

When the electric pump is in the temperature control mode, the electric pump can change its operating state at any time according to the different gear temperature Settings.

1) TC 1(Indicator 1 light on): set the temperature to 10℃, when the temperature sensor detects that the pump body temperature is lower than 10℃, the pump accelerates; When the temperature is higher than 10 ° C, the pump decelerates, and the temperature of the pump body is maintained at 10 ° C.

2) TC 2(Indicator 2 light on): Set the temperature to 20℃, when the temperature sensor detects that the pump body temperature is lower than 20℃, the pump accelerates; When the temperature is higher than 20 ° C, the pump decelerates, and the temperature of the pump body is maintained at 20 ° C.

3) TC 3(Indicator 3 light on): Set the temperature to 30℃, when the temperature sensor detects that the pump body temperature is lower than 30℃, the pump accelerates; When the temperature is higher than 30 ° C, the pump decelerates, and the temperature of the pump body is maintained at 30 ° C.

4) TC 4(Indicator 4 light on): Set the temperature to 40℃, when the temperature sensor detects that the pump body temperature is lower than 40℃, the pump accelerates; When the temperature is higher than 40 ° C, the pump decelerates, and the temperature of the pump body is maintained at 40 ° C.

5) TC 5(Indicator 5 light on): Set the temperature to 50℃, when the temperature sensor detects that the pump body temperature is lower than 50℃, the pump accelerates; When the temperature is higher than 50 ° C, the pump decelerates, and the temperature of the pump body is maintained at 50 ° C.

6) TC 6th gear (Indicator 1 light and Indicator 5 light are on at the same time): Set the temperature to

60 ℃. When the temperature sensor detects that the pump body temperature is below 60 ℃, the water pump accelerates; When the temperature exceeds 60 ℃, the water pump slows down to ensure that the temperature of the pump body is maintained at 60 ℃.

7) TC 7th gear (Indicator 2 light and Indicator 5 light are on at the same time): Set the temperature to

70 ℃. When the temperature sensor detects that the pump body temperature is below 70 ℃, the water pump accelerates; When the temperature exceeds 70 ℃, the water pump slows down to ensure that the temperature of the pump body is maintained at 70 ℃.

8) TC 8th gear (Indicator 3 light and Indicator 5 light are on at the same time): Set the temperature to

80 ℃. When the temperature sensor detects that the pump body temperature is below 80 ℃, the water pump accelerates; When the temperature exceeds 80 ℃, the water pump slows down to ensure that the temperature of the pump body is maintained at 80 ℃.

9) TC 9th gear (Indicator 4 light and Indicator 5 light are on at the same time): Set the temperature to

90 ℃. When the temperature sensor detects that the pump body temperature is below 90 ℃, the water pump accelerates; When the temperature exceeds 90 ℃, the water pump slows down to ensure that the temperature of the pump body is maintained at 90 ℃.

10) TC 10 gear (Indicator 1 light, Indicator 4 light, and Indicator 5 light are on at the same time): Set the temperature to 100 ℃. When the temperature sensor detects that the pump body temperature is below 100 ℃, the water pump accelerates; When the temperature exceeds 100 ℃, the water pump slows down to ensure that the temperature of the pump body is maintained at 100 ℃.

6、0-10V analog signal control

1) When the electric pump is in the 0-10V control mode, the pump adjusts the operating status of the water pump based on the level range of the input analog signal.

2) When connecting 0-10V signals, the gear must be manually switched to VC gear before speed regulation can be carried out; Similarly, exiting the 0-10V control also requires manual switching to other gears.

Motor type

|

Motor type: permanent magnet synchronous motor |

Enamelled wire material:copper |

Magnetic steel material: neodymium iron boron |

|

DC cold resistance of motor at 20 ℃:4.0±5%Ω |

Insulation level :H |

|

Media requirements for use

|

Medium used: water or a mixture of water and ethylene glycol (≤ 50%) |

Medium water temperature: -10 ℃~110℃( use temperature≤ 65 ℃ in domestic hot water to reduce the risk of calcium carbonate scaling) |

|

Medium pH value: 6.5~8.5 |

Medium hardness: 25° dH |

|

Solid impurity content in the medium: The diameter and length direction of solid impurities are ≤0.1mm, and the volume ratio is ≤ 0.1%. |

|

Environmental requirements for use

|

Usage: Keep the axis horizontal |

Altitude: < 1000m |

|

Operating environment temperature: 0 ℃~40 ℃ (There is no freezing phenomenon in the pipeline and circulating pump) |

Operating environment humidity ≤95% |

Storage environment requirements

|

Storage environment temperature:-20℃~70℃ (There is no freezing phenomenon in the pipeline and circulating pump) |

Storage environment humidity ≤ 95% |

Comparison Table of Water Temperature and Inlet Pressure

|

liquid temperature |

<50℃ |

95℃ |

110℃ |

|

inlet pressure |

0.2bar |

0.5bar |

0.85bar |

|

1 meter lift |

5 meter lift |

8.5 meter lift |

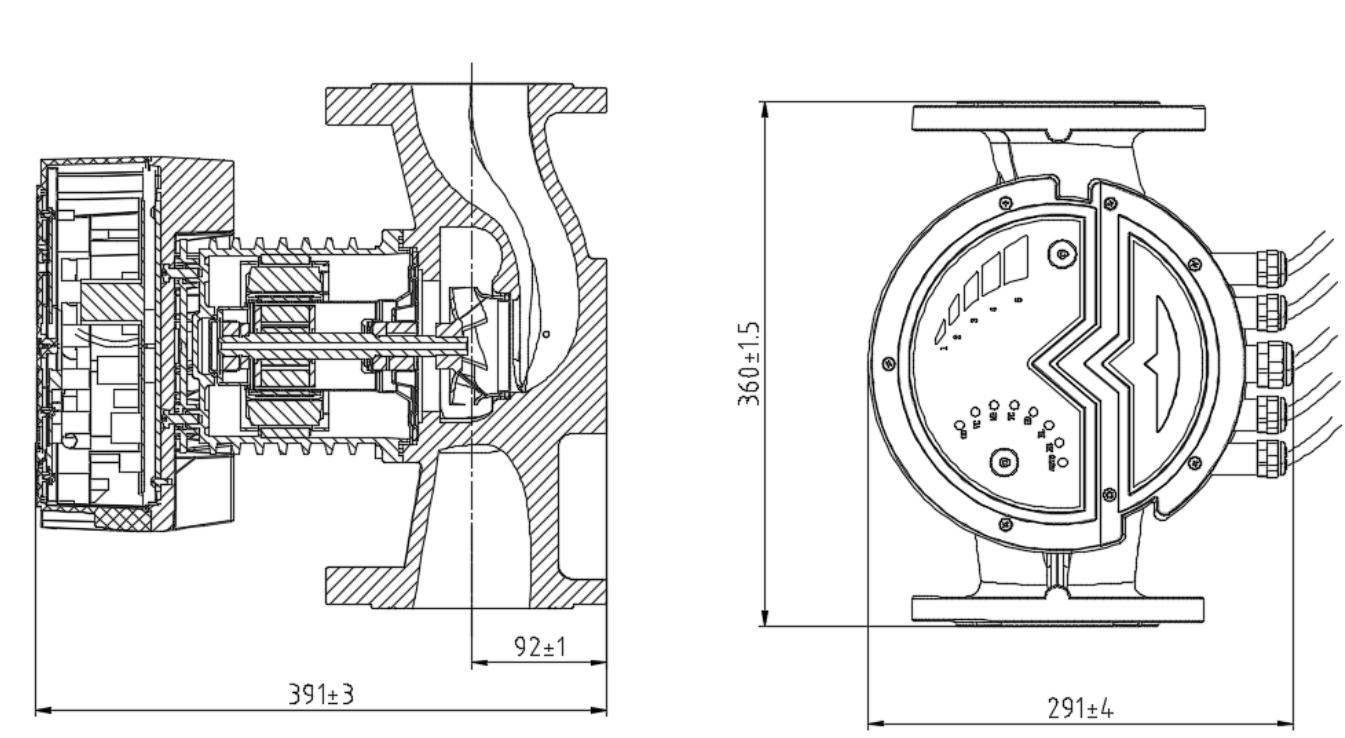

Installation Drawing

Tags :